Why Construction in Today’s Market Demands a Strategic Advisor, Not Just a Builder

In an era of economic uncertainty and shifting market dynamics, successful construction projects require strategic consultation from day one. At KasCon, we’ve evolved from traditional contractors into trusted consultants – and we’ve discovered that our greatest value often comes not from what we build, but from the strategic guidance we provide before the first shovel hits the ground.

The New Reality: When the Numbers Don’t Add Up

Construction costs have skyrocketed while rental rates remain stagnant. What used to cost, for example,$70.00 per square foot now costs $125.00, but the $30 per square foot rent hasn’t budged. This fundamental shift has created a crisis of project viability that’s forcing property owners to completely rethink their approach.

We’re seeing deals revisited three and four times as owners struggle with projects that simply don’t pencil out. The traditional model of “build it and they will pay” no longer works in today’s economic climate. Projects are going to the shelf, waiting for market conditions to align or for creative solutions to emerge.

From Contractor to General Business Advisor

This market reality has increased the value of what KasCon has always provided our clients – going beyond traditional construction to business advisors helping clients navigate complex financial decisions. When a client needs their project to work at $2 million but our numbers show $2.5 million, we don’t just deliver bad news. We put on our consultant hat and work collaboratively to find alternative solutions.

Real-world example: A medical practice wanted to purchase an $850,000 building that would require $350,000 in renovations for more space than they needed. Rather than simply providing the construction estimate, we advised them to walk away and leveraged our network to connect them with a better opportunity – a new space in a development where they could own a condo unit at a fraction of the total cost.

This comprehensive advisory approach has become essential for project success. As true partners and advisors we’re not just asking “how much will this cost?” but “does this make business sense, and if not, what are the alternatives?”

The Relationship-Driven Market

Today’s construction market is completely relationship-driven. Success depends not just on competitive pricing, but on trust, experience, and the ability to provide comprehensive guidance beyond traditional construction.

owners need a general contractor who understand:

- Market dynamics affecting project feasibility

- Alternative approaches when Plan A doesn’t work

- The broader business implications of construction decisions

- How to navigate complex lease and purchase negotiations and property evaluations

- Financial structuring options that optimize project outcomes

The KasCon Advantage

What sets KasCon apart in this challenging environment is our comprehensive approach that goes far beyond traditional contracting. We serve as:

- Strategic construction consultants who can help evaluate deal feasibility before you commit capital

- Market connectors who leverage our network to introduce you to the right professionals for your specific needs

- Business advisors focused on your project’s overall success, not just our construction contract

- Experienced guides who can spot potential issues before they become expensive problems

- Lease and Purchase advisors who identify construction-related pitfalls in lease and purchase agreements

Conclusion

The construction industry is evolving rapidly, and so is the role of construction professionals. Today’s successful projects require contractors who understand that building expertise is just the foundation. Real value comes from strategic thinking, market knowledge, relationship networks, and the experience to guide clients toward decisions that make both construction and business sense.

At KasCon, we’ve embraced our role as advisors and consultants – we’re not just building structures, we’re building successful outcomes for our clients. In a market where the difference between profit and loss often comes down to early-stage decision making, having the right general contractor can make all the difference.

Ready to discuss your next project? Contact KasCon to learn how our consulting approach can help ensure your project’s success from concept to completion.

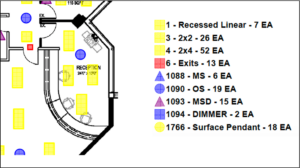

Instead, we create preliminary lighting layouts based on the intended use and space requirements, then count actual fixture quantities to provide far more accurate pricing (example on left).

Instead, we create preliminary lighting layouts based on the intended use and space requirements, then count actual fixture quantities to provide far more accurate pricing (example on left).